Most old antique clocks stop running properly because they suffer from years of normal "wear-and-tear". When this wear-and-tear becomes severe, the clock fails to operate properly, or fails to operate at all. (Running 24 hours a day, 7 days a week, for a decade or more, takes a toll on all the springs, gears, wheels, bearings, metal parts, and other areas inside the clock). Did you know that most mantel clocks will "tick" and "tock" about 600 million times in just 10 years of use?

There is a misconception that clocks "last forever"…..they do not.

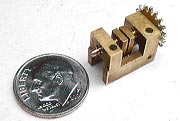

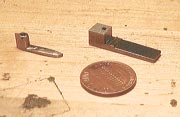

The companies that manufactured these old clocks are all long gone out-of-business. Replacement parts are simply not available in most cases. So custom-machined components often have to be manufactured, and fitted, as replacements.

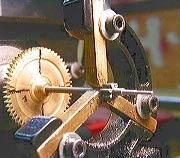

I can design, make, and install many such replacements. Below are just a few examples of the parts repair and manufacturing I have handled in the past. (These are some old photographs from my very early work; in 2010 the site will be updated with more recent photos. I have done substantially more than is seen here today).

JFK is equipped with the engine and toolmakers' lathes, the milling equipment, and the gear cutting equipment that is required to do the work such as is seen below. Replacement wheels (gears), pivots, bearings, arbors, and barrels, and their proper fitting into your clock, are within JFK's capabilities.

Whatever part your clock needs "custom made", JFK has probably made one before and can do it again.